Home > Insight > IT Business

Customization Features: The Key to Effective ERP for Manufacturing Industry

5 minutes read

Audio description available

December 20, 2024

The ERP for manufacturing industry plays a crucial role in streamlining production processes, managing resources, and enhancing overall efficiency. While these systems have revolutionized the way businesses operate, many manufacturers face challenges with standard ERP solutions that lack the flexibility to address their specific needs. Customization features have become essential for creating ERP systems that align with unique manufacturing workflows, improve decision-making, and ensure long-term scalability. This blog will explore the key benefits of customized ERP systems, highlights important criteria for selecting the right solution, and introduces top ERP options tailored for your manufacturing success!

1. Why customization matter in ERP for manufacturing industry

An ERP for manufacturing industry is a centralized software solution designed to manage and automate business processes. It connects core functions like production planning, inventory management, supply chain, and finance, enabling seamless coordination across departments.

According to Fortune Business Insights, the global ERP software market is expected to grow from $63.57 billion in 2023 to $145.58 billion by 2030, with manufacturing being one of the largest contributors. This growth highlights the increasing need for ERP systems to handle complex workflows in modern manufacturing.

Real-time data sharing in an ERP system for manufacturing ensures better decision-making and minimizes errors. A Grand View Research report indicates that manufacturers implementing ERP see up to a 20% increase in operational efficiency.

As manufacturing processes become more complex, relying on a one-size-fits-all ERP system is no longer sufficient. Companies are shifting to customized ERP solutions to meet their specific needs, improve productivity, and stay competitive in an evolving market.

Read more: ERP For Retail Industry: Why Odoo is Essential

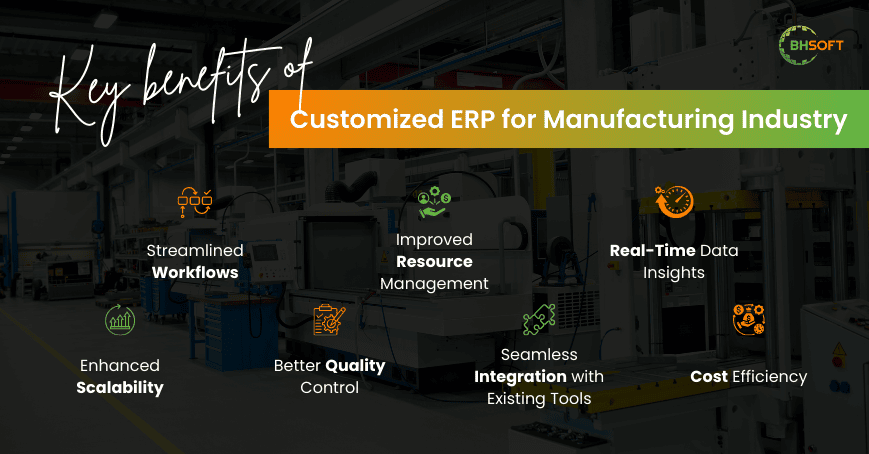

2. Key benefits of a customized ERP for manufacturing systems

A customized ERP for manufacturing systems is a powerful tool that helps businesses achieve operational excellence. Unlike standard solutions, it is tailored to fit the specific needs of manufacturers, offering flexibility and efficiency that off-the-shelf systems cannot match. Here are the key benefits:

A customized ERP for manufacturing systems is a powerful tool that helps businesses achieve operational excellence. Unlike standard solutions, it is tailored to fit the specific needs of manufacturers, offering flexibility and efficiency that off-the-shelf systems cannot match. Here are the key benefits:

2.1. Streamlined Workflows

Customized ERP systems optimize manufacturing processes by automating repetitive tasks and improving coordination across departments. This ensures smoother operations and faster production cycles.

2.2. Improved Resource Management

With tailored features, an ERP for manufacturing industry provides real-time insights into inventory, labor, and equipment. This allows manufacturers to allocate resources effectively and reduce waste.

2.3. Real-Time Data Insights

Customized ERP solutions provide accurate, up-to-date information. Manufacturers can monitor production, analyze performance, and make informed decisions that improve efficiency.

2.4. Enhanced Scalability

A custom ERP system grows with your business. Whether expanding production or adapting to new market demands, it ensures your system evolves alongside your operations.

2.5. Better Quality Control

Customization enables manufacturers to track and enhance product quality at every stage of production. This leads to fewer defects, higher customer satisfaction, and improved compliance with industry standards.

2.6. Seamless Integration with Existing Tools

A customized ERP integrates effortlessly with your existing systems, such as accounting, CRM, or shop-floor devices. This eliminates data silos and ensures a unified flow of information.

2.7. Cost Efficiency

While tailored solutions may involve an upfront investment, they significantly reduce long-term costs by minimizing errors, improving efficiency, and avoiding production delays.

Investing in a customized ERP for manufacturing systems empowers businesses to optimize their operations, boost productivity, and remain competitive in a dynamic market.

Learn more: Custom ERP Software Development: Tailored Solutions for Your Business

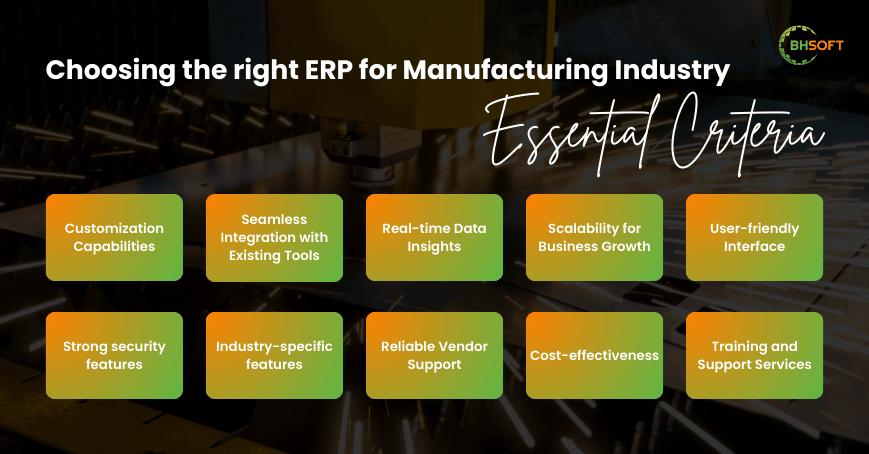

3. Choosing the right ERP for Manufacturing Industry: Essential Criteria

Selecting the right ERP for manufacturing industry is critical for optimizing workflows, improving decision-making, and ensuring long-term success. Here are the key factors to consider when choosing an ERP system:

3.1. Customization Capabilities

Manufacturing processes are unique to each business. Your ERP must allow deep customization to match specific operational needs. A customized ERP for manufacturing systems can adapt to production planning, inventory control, and quality management requirements. Tailored solutions ensure your ERP aligns with your business workflows.

3.2. Seamless Integration with Existing Tools

Your ERP should integrate smoothly with current tools like CRM, accounting software, and IoT devices. This ensures a unified flow of information, reduces duplication, and prevents data silos. For example, integrating production and financial systems provides real-time cost analysis and better budget management.

3.3. Real-Time Data Insights

Choose an ERP that offers advanced real-time data tracking and analytics. Accurate and up-to-date information allows you to monitor production schedules, track performance, and make quick, informed decisions. Real-time insights help you address potential disruptions, such as low inventory levels, before they impact operations.

3.4. Scalability for Business Growth

A scalable ERP system for manufacturing grows with your business. It should handle increasing production volumes, support new locations, and accommodate more users. Scalability ensures your ERP can adapt to future changes, such as entering new markets or expanding product lines.

3.5. User-Friendly Interface

An intuitive ERP interface reduces training time and boosts productivity. Employees can quickly learn how to use the system, minimizing downtime. Clear dashboards and role-based views help users focus on relevant tasks, improving efficiency across teams.

3.6. Strong Security Features

Manufacturing involves handling sensitive data, such as production schedules and financial records. Your ERP must include robust security measures like encryption, multi-factor authentication, and role-based access controls. Regular updates and compliance with industry standards help protect your data from threats.

3.7. Industry-Specific Features

Look for an ERP that offers tools tailored to manufacturing, such as production scheduling, batch tracking, and compliance monitoring. These features ensure that the system supports your unique industry requirements, improving efficiency and meeting regulatory demands.

3.8. Reliable Vendor Support

Choosing a reliable ERP provider is as important as selecting the system itself. A good vendor will offer:

- Expertise in ERP customization.

- Solutions tailored to your industry needs.

- Ongoing support for updates, maintenance, and troubleshooting.

Partnering with a trusted provider ensures smooth implementation and helps you maximize the system’s value.

3.9. Cost-Effectiveness

An ERP solution must deliver value without exceeding your budget. Consider the total cost of ownership, including installation, training, maintenance, and upgrades. A cost-effective ERP provides essential features while allowing you to add modules as your needs grow.

3.10. Training and Support Services

The effectiveness of an ERP system depends on how well your team can use it. Select a vendor that offers comprehensive training programs to help users understand the system. Reliable support ensures quick issue resolution and allows you to adapt the ERP as your business evolves.

By focusing on these essential criteria, you can choose the right ERP for manufacturing industry to streamline operations, improve efficiency, and position your business for future growth.

Learn more: Web UI For Terminal-Based Programs

4. Top 5 ERP Software for Manufacturing Industry

Choosing the right ERP for manufacturing industry is essential for improving efficiency, streamlining workflows, and supporting long-term growth. Here’s a comparison of the top ERP solutions tailored for manufacturing, highlighting their strengths and weaknesses.

4.1. NetSuite ERP

NetSuite is a leading cloud-based ERP platform widely used in the manufacturing sector. It provides robust modules for managing production schedules, inventory, procurement, and financial planning, making it suitable for manufacturers with diverse operational needs. The platform is designed to support businesses looking for real-time visibility across their operations, helping them make data-driven decisions.

Strengths:

- Fully customizable dashboards and workflows for production planning and inventory management.

- Strong integration capabilities with third-party tools.

- Real-time analytics for improved decision-making.

Weaknesses:

- High upfront costs and ongoing subscription fees.

- Limited flexibility for niche industries or highly specific workflows.

- Customization is dependent on external consultants, increasing costs and time.

4.2. SAP Business One

SAP Business One is a reliable and scalable ERP solution specifically tailored for manufacturing firms that require a balance between advanced features and affordability. Known for its efficiency, the platform simplifies core manufacturing processes such as production planning, inventory management, and compliance tracking.

Strengths:

- Scalable design to grow with your manufacturing operations.

- Advanced reporting tools for tracking production and sales.

- Seamless integration with IoT devices for enhanced shop-floor automation.

Weaknesses:

- Expensive implementation and maintenance, especially for smaller businesses.

- User interface can be challenging for non-technical teams.

- Limited customization compared to open-source solutions.

4.3. Microsoft Dynamics 365

Microsoft Dynamics 365 is a flexible, cloud-based ERP solution that integrates seamlessly with the Microsoft ecosystem, including tools like Excel, Teams, and Power BI. It is designed for manufacturers seeking a modular system where they can select and implement only the features they need. The platform offers specialized tools for managing production workflows, supply chain logistics, and customer interactions.

Strengths:

- Modular system that allows businesses to choose and integrate only the necessary features.

- Real-time visibility into production processes.

- AI-driven insights to optimize workflows and reduce waste.

Weaknesses:

- Complex implementation process requiring significant time and resources.

- High licensing costs for larger teams or additional modules.

- Customization options are limited within pre-defined parameters.

4.4. Infor CloudSuite Industrial (SyteLine)

Infor CloudSuite Industrial is a specialized ERP solution designed for manufacturers in both discrete and process industries. It offers a range of advanced tools for production scheduling, inventory control, and analytics, making it a go-to choice for businesses with complex operational requirements.

Strengths:

- Strong industry focus with tools for niche manufacturing processes.

- Powerful analytics for tracking and improving key production metrics.

- Easy customization of production schedules and workflows.

Weaknesses:

- Higher costs for cloud services compared to on-premise ERP options.

- Limited support for non-standard manufacturing operations.

- Requires ongoing vendor support for major customizations.

4.5. Custom-Built Odoo ERP

Odoo ERP stands out as an open-source, modular ERP solution offering complete customization for manufacturing businesses. Unlike other solutions, it gives manufacturers full control over every aspect of their ERP, from production planning to reporting tools. The system is designed for businesses looking for tailored solutions that fit their unique workflows, rather than settling for pre-configured modules.

Strengths:

- Odoo’s open-source framework allows businesses to create an unlimited customized ERP that aligns with their unique manufacturing processes.

- The modular pricing structure ensures you only pay for the features you need, making it cost-effective.

- Odoo integrates with existing tools, such as accounting software, CRMs, and IoT devices, for a unified workflow.

- Scalability allows the system to grow with your business, adapting to evolving needs like expanded production lines or new locations.

- With a comprehensive control, manufacturers can modify everything, from production workflows to reporting dashboards, without limitations

Weaknesses:

- Building a comprehensive and highly customized Odoo ERP requires significant time and collaboration with developers.

- The extensive customization options may require additional training for teams to use the system effectively.

Custom-built Odoo ERP ensures that manufacturers receive a solution tailored specifically to their needs, making it a smart investment for long-term success. It allows businesses to achieve the perfect balance between flexibility, cost-efficiency, and scalability.

Case Study: TOYOTA

Toyota implemented Odoo as its ERP for manufacturing. In just six months, the system streamlined their operations. Toyota used Odoo to integrate production workflows, manage inventory, and enhance reporting accuracy. This led to improved efficiency and better coordination across departments. Odoo’s flexibility allowed Toyota to customize features to their specific needs, showcasing how even large enterprises benefit from this adaptable ERP solution.

Conclusion

Customization and integration are the cornerstones of an effective ERP for manufacturing industry. By tailoring ERP systems to meet specific business needs and ensuring seamless integration with existing tools, manufacturers can unlock streamlined operations, better decision-making, and improved productivity.

Choosing the right ERP solution for manufacturing requires careful planning and a focus on flexibility and efficiency. Whether it’s enhancing production workflows, integrating real-time data, or simplifying inventory management, a customized ERP system empowers manufacturers to stay competitive and adapt to changing demands.

If you are looking to optimize your manufacturing firm's operations, exploring BHSoft’s Odoo Customization Solutions can be a step toward achieving operational excellence. A well-implemented ERP not only supports growth but also positions manufacturers for long-term success in an increasingly complex market.

Ready to take your manufacturing processes to the next level? Start by investing in a customized ERP solution that works for your business with BHSoft!